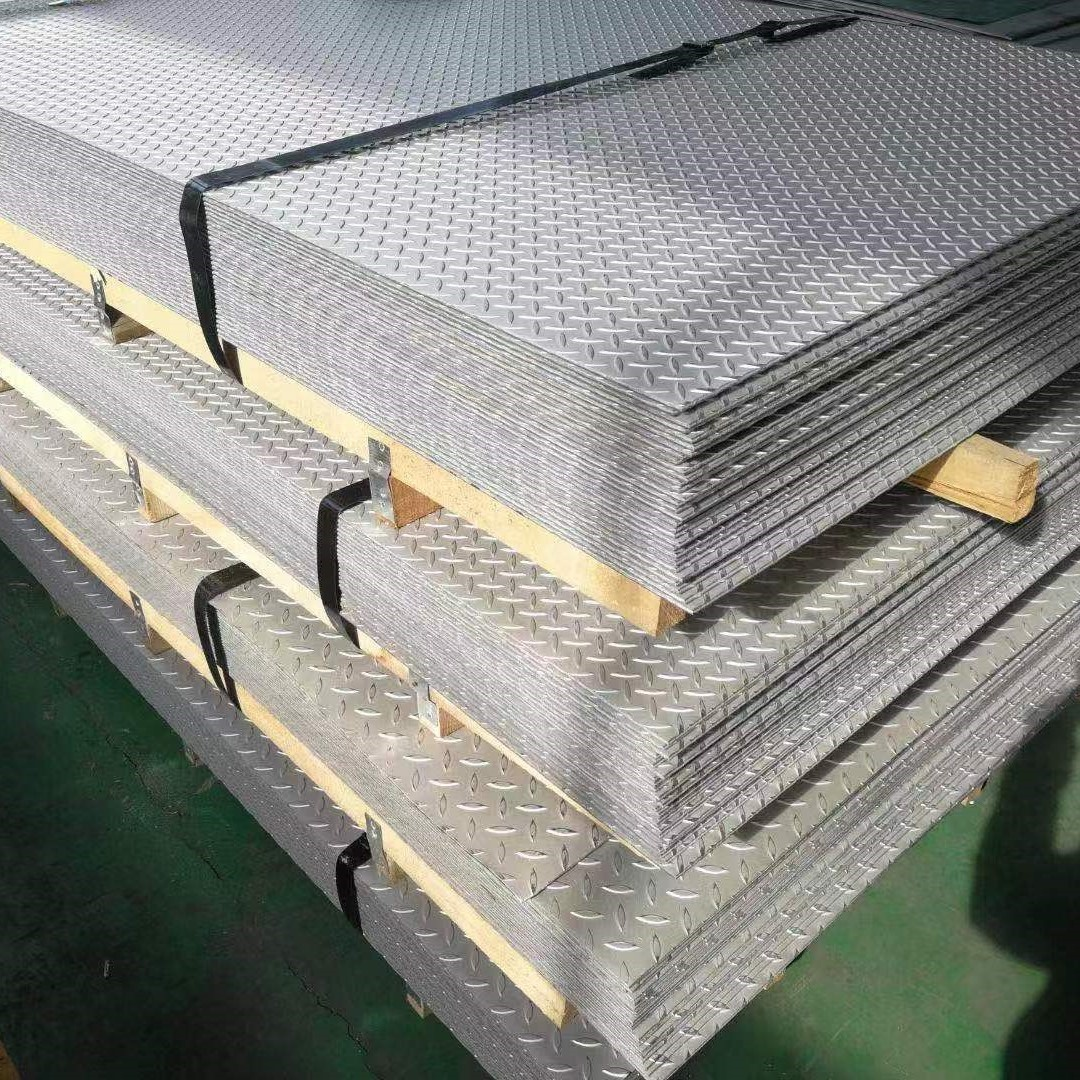

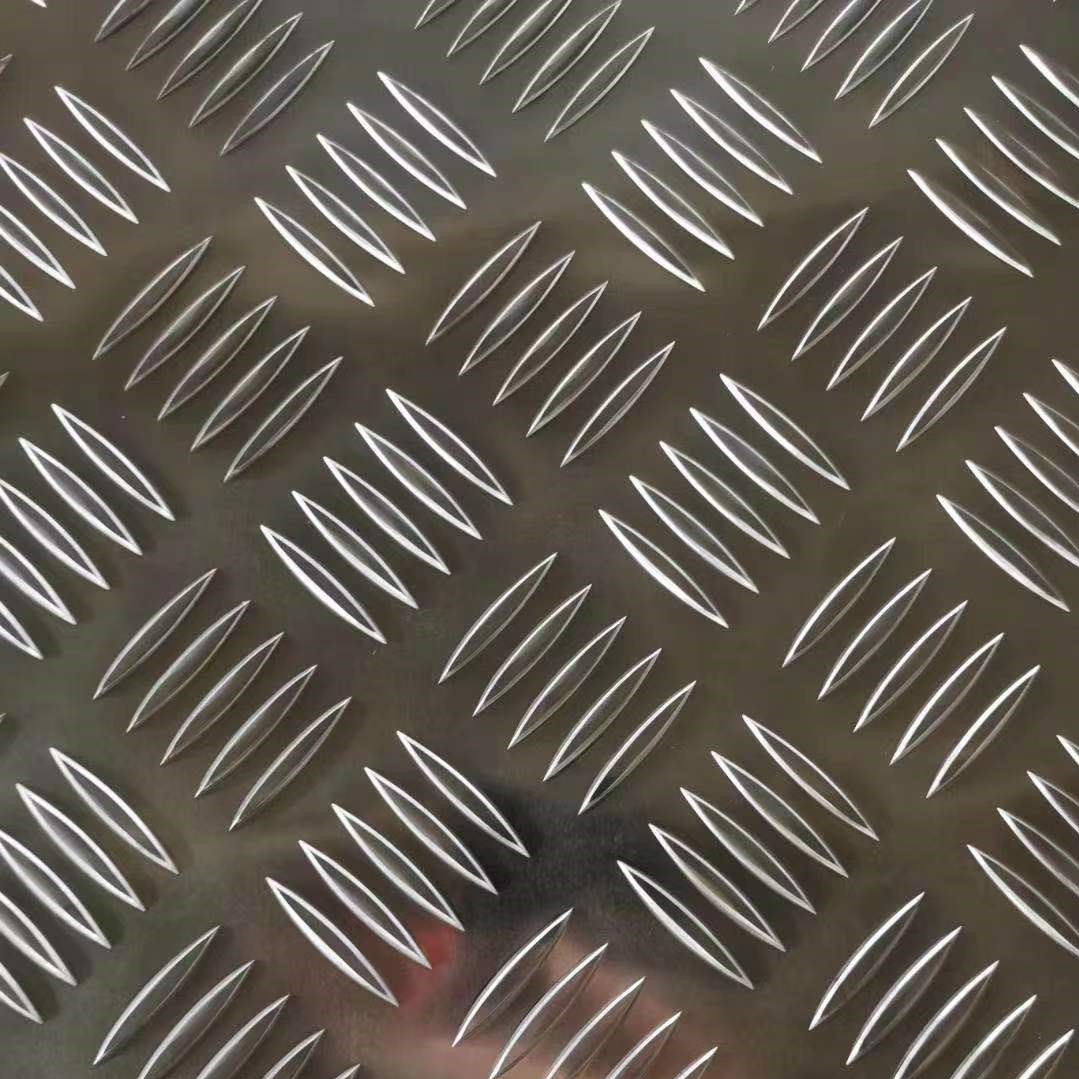

Hot Sale Embossed Stainless Steel Plate 304 316 310s 904l Stainles S Steel Sheet

| Product name | Colored Stainless Steel Plate |

| Main business | stainless steels, nickel alloys, carbon steels |

| Wall Thickness | 0.1-100mm or customized |

| Authentication | ISO9001 |

| Width | 1000/1219/1500mm or customized |

| plateType | ±5% |

| Processing services | Bending, Cutting |

| Grade | 316/316L/904L |

| Material | 300 series/900 series/other |

| Edge | Mill Edge, Slit Edge |

| Packing | standard exporting packing |

1, the product surface is covered with PE protective film, thickness of 3C/5C/7C/10C.

2, the follow-up can be titanium plating, no fingerprint and other deep processing.

3, there are more than 20 patterns, the number can be customized mold.

Architecture, elevator decoration application;Household appliances, kitchenware application;Electronic and electrical enclosure applications;Mesa panel application;Door frame application;Seat contact application.

Durable, durable, wear-resistant, decorative effect is strong. Beautiful vision, good quality, easy to clean, maintenance free, anti - pressure, anti - scratch and leave no finger marks. Stainless steel embossing plate is suitable for decorating elevator car, subway car, all kinds of cabin body, architectural decoration and decoration, metal curtain wall industry.

Generally speaking, the use of stainless steel embossed plate metal decorative column, is composed of skeleton, base plate and decorative panel three parts.

1, skeleton approach

The skeleton has two kinds of wood structure and steel structure. Wooden structure skeleton is made of square wood, mainly used for pasting a variety of colorful stainless steel plate decoration materials. Steel structure skeleton by Angle steel welding or bolt connection, this structure is used to paste aluminum alloy plate decorative plate. Now take the concrete square column enclosed column as an example, briefly talk about the method of skeleton: firstly, the vertical skeleton is positioned through the embedded parts, the connection between the horizontal and vertical skeleton and the skeleton support and the column body is fixed, the diameter of the circular column needs to be determined.

2, the fixing of the base plate

The function of the base plate is to increase the stiffness of the column skeleton and facilitate the paving of decorative panels. It is generally made of plywood, woodboard or density board, and the base board is fixed directly to the skeleton with iron nails or screws. The base plate must have a smooth surface and high dimensional accuracy, in order to ensure the installation quality of the decorative surface of the color stainless steel plate, which is higher on the occasion of the package stick cylinder.

3. Installation of colored stainless steel decorative panel

In the installation and fixing of color stainless steel plate decoration materials, usually using adhesive, nailing two ways, not suitable for the use of welding, because the high temperature of welding will destroy the surface of the color of the film layer, ultimately affect its beauty; Especially color stainless steel mirror plate, the surface is a mirror, if it is a single color, then welding will leave an indelible stain, will lose the overall decorative effect; So the use of this material decoration application welding method is relatively less. The adhesive method is easy to operate, so it is the most widely used. Nailing method is easy to install and firm, but the decorative surface will also be affected. No matter which installation method is used, it must be necessary to cut the sheet accurately.