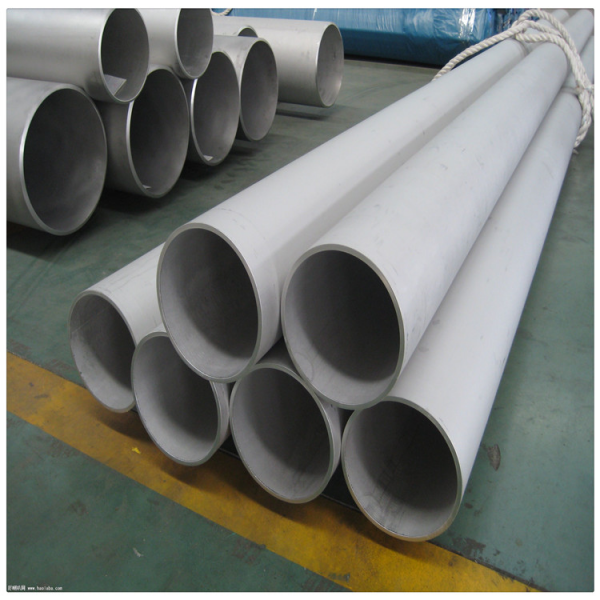

Factory Price Welded Stainless Steel Pipe 304 304L 316 316L Stainless Steel Tube

| According to your request,each size can be selected for different application.Please contact us! | |

| Product Name | Stainless Steel Round Pipe/Tube |

| Length | As required |

| Thickness | 0.5-100mm or as required |

| Standard | ASTM A213,A312,ASTM A269,ASTM A778,ASTM A789,DIN 17456, DIN17457,DIN 17459,JIS G3459,JIS G3463,GOST9941,EN10216, BS3605,GB13296 |

| Technique | Hot Rolled , Cold Rolled , Extrusion |

| Surface | be customized as customers' requirements |

| Thickness Tolerance | ±0.01mm |

| Material | 304,304L,309S,310S,316,316Ti,317,317L,321,347,347H,304N,316L, 316N,201,202 |

| Application | Widely used in petroleum,foodstuff,chemical industry,construction, electric power,nuclear,energy,machinery,biotechnology,paper making,shipbuilding,boiler fields.Pipes also can be made according to the customer's required. |

| MOQ | 1 ton , We can accept sample order. |

| Shipment Time | Within 7-15 workdays after receiving deposit or L/C |

| Export Packing | Standard seaworthy export packing or according to the customers' request |

| Capacity | 25000 Ton/Tons per Month |

Surface resistance less than 1000 megabytes; Wear protection; Scalable; Excellent chemical resistance; Good resistance to alkali metals and acidity; Strong toughness; Flame retardant.

Stainless steel welded pipe production process:

Raw materials -- strip -- welded pipe -- repair end -- polishing -- inspection (printing)-- packaging -- shipping (warehousing)(decorative welded pipe).

Raw material - article points - welding pipe, heat treatment, correct, straightening, fix the end, pickling, water pressure test, inspection (spurts India) - packaging - shipment (transport) (tube) for piping weld pipe industry.

Chloride ions are found in many places, such as salt, sweat, sea water, sea wind, soil, and so on. In the presence of chloride ions in the environment of stainless steel, corrosion quickly, even more than ordinary mild steel, chloride ions and alloy elements of Fe form a complex, Fe positive potential reduction, and then oxidized by oxidant to take away electrons.

So there are requirements for the use of stainless steel environment, and the need to wipe often, remove dust, keep clean and dry.

316 and 317 stainless steels are molybdenum-containing stainless steels. The molybdenum content of 317 stainless steel is slightly higher than 316 stainless steel. Because 316 stainless steel contains molybdenum, the overall performance of the steel is better than 310 and 304 stainless steel, under high temperature conditions, when the concentration of sulfuric acid is lower than 15% and higher than 85%, 316 stainless steel has a wide range of uses. 316 stainless steel also has good resistance to chloride corrosion, so it is commonly used in Marine environments.